In today’s world, every device tends to have a specific purpose, and most humans are increasingly specialized in their work. The same is true for industrial robots. Countless specialized jobs are now possible thanks to robots designed with ranges of movement and features perfect many tasks.

One of the most common and widespread types of industrial robots are articulated robots.

Read on to find the tasks that will let your factory best benefit from the unique features articulated robots feature.

What is an articulated robot?

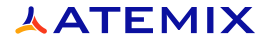

When anyone mentions industrial robots or speaks about them, they usually speak about articulated robots, the most commonly used industrial robots. An articulated robot is a robot with rotary joints. The number of rotary joints or axes can range from 2 to 10, but robots usually have 4-6 such joints. Every additional joint gives the robot more freedom of movement – in fact, articulated robots have more degrees of freedom than any other robot types currently available, giving them the versatility that manufacturers seek.

What types of manufacturing processes are best suited for articulated robots?

The large work envelope of articulated robots enables to use them for a number of different operations from material handling, welding, and assembling, to painting, spraying, and cutting. Thanks to the miniaturization of electronic equipment, they are increasingly helpful for industries ranging from heavy manufacturing to foods and beverages.

What are the benefits of articulated robots?

In addition to the versatility mentioned above, articulated robots are swift and accurate, enabling them to produce more, faster. Their precision also increases quality, boosting client satisfaction.

As articulated robots have become the most popular type of industrial robots, they are becoming increasingly affordable for small and mid-sized manufacturers. The longevity and great availability of their spare parts make them relatively low maintenance and therefore a wise investment.

Why integrate articulated robots to manufacturing processes with the help of Woboton?

As appealing as articulated robots may sound, it is not wise to make any investments into industrial automation or robotics without knowing their exact impact on your manufacturing processes and profitability. In our time we have seen several high-end industrial robots gathering dust in the corner.

Any investment in robotics and digitalization should be made after assessing the current state of the factory, and finding out which manufacturing processes are the first and most important ones to benefit from robotic solutions. Woboton helps you not only integrate robotic solutions but invest in the right solutions to boost both profitability and productivity.

We collaborate with world’s leading industrial robot and software manufacturers to ensure the longevity and easy maintenance of our solutions. With over 17 years of experience, we know how to raise manufacturing to new levels of quality.

Interested in implementing industrial robotics solutions? Get in touch with us!

We create our industrial robots solutions in collaboration with:

Kassisilma 4, 61708, Tartumaa, Estonia

Kassisilma 4, 61708, Tartumaa, Estonia