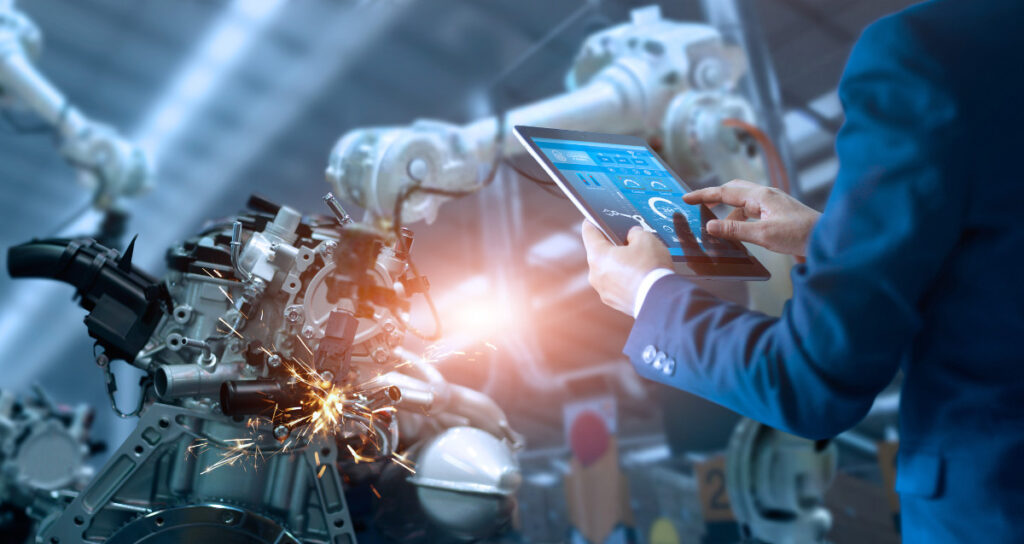

Industry 4.0 will forever change the face of manufacturing and, frankly, life as we know it – as did the first three industrial revolutions. It is the basis of the concept “smart anything” which will soon lead to smarter device, smart buildings, smart grids etc. But not to get ahead of ourselves, what are the 10 main benefits of implementing Industry 4.0 solutions for factories and businesses?

Personalized products

Industry 4.0 is a way to move away from mass production and towards more personalized products. Some even say that the level of customization resembles crafts manufacturing. The several industrial revolutions led us to a production process where we could produce thousands of identical products faster, with higher quality and more efficiently. But every customization meant that some of the machinery or even the whole factory needed to be set up accordingly – which caused expensive downtime.

The solutions of Industry 4.0 help us produce individualized products without additional setups or human interference – which means that the clients do not have to necessarily order in bulk in order to keep the product cost down and can afford more specific personalization to their products.

Artificial intelligence, machine learning, Industrial Internet of Things and other parts of Cyber Physical systems help us personalise products to an individual but at the same time employ mass production techniques – which is the most important benefit of the new industrial revolution.

Higher productivity and better efficiency

Industry 4.0 helps you do more with less. This means a faster production process that uses less raw materials and production resources to produce more while keeping the costs down.

As the human input is minimal and machines have enhanced monitoring systems, the smart factories benefit from less downtime, because preventive maintenance can be done at the right moment. It also helps to locate any production-related problems in real time and solve them with adequate data in hand.

The production unit as a whole will be more efficient, because the different areas of the production unit are aware of the workloads of each line and device.

As the machines are able to do production-related decisions according to the sensory input and collected data, they can optimize production processes to produce more and faster. Combined with automated reporting and connectivity with resource management softwares, a smart factory helps make better business decisions.

Reduced costs

The initial investments for implementing Industry 4.0 solutions are substantial but change does not happen overnight or on its own. However, when transition to a smart factory has been made, in addition to better productivity you will be able to see a considerable cost reduction.

Let’s look at it this way: smart factory helps to use resources more efficiently, reduces downtime dramatically, helps to manufacture faster, with better quality, less material and product waste and low operating costs.

When you add up the positives and avoid dealing with the negatives, the impact on your manufacturing processes is substantial.

Higher quality and better customer experience

In addition to the enhanced production capabilities of smart factories, they also hold the key to better customer experience. Industry 4.0 enables to implement solutions for better product tracking to identify problematic products and quickly find out the reasons behind the defects.

But most importantly, as long as the production machinery and software are in order, smart factories are able to produce products with exceptional quality on a regular basis. This means that the customers can rely on the quality of the products and your business has to deal less with complaints, recalls and problem solving.

Increased profitability

We have covered higher quality and efficiency, better costs and better customer experience, which all add up to better profitability. In addition to that, smart factories enable businesses to develop new and innovative products considerably faster, and even offer customers personalised products. Industrial Internet of things, machine learning and other Industry 4.0 solutions show businesses new and profitable possibilities in the digitalized world.

Woboton – Robotics. Industry 4.0

If your company had the chance to get all the benefits mentioned above, wouldn’t it take the opportunity? Woboton will help you make the first steps on the way to a fully automatic smart factory – implementing the solutions of Industry 4.0 in the way that best suits your factory. Let’s take this leap together. We can assure you that these investments will pay off – and we will be there for you every step of the way.

Kassisilma 4, 61708, Tartumaa, Estonia

Kassisilma 4, 61708, Tartumaa, Estonia