At Woboton, we want to find the right solutions for digitalization and robotics that will quickly lead to the highest profitability and productivity growth!

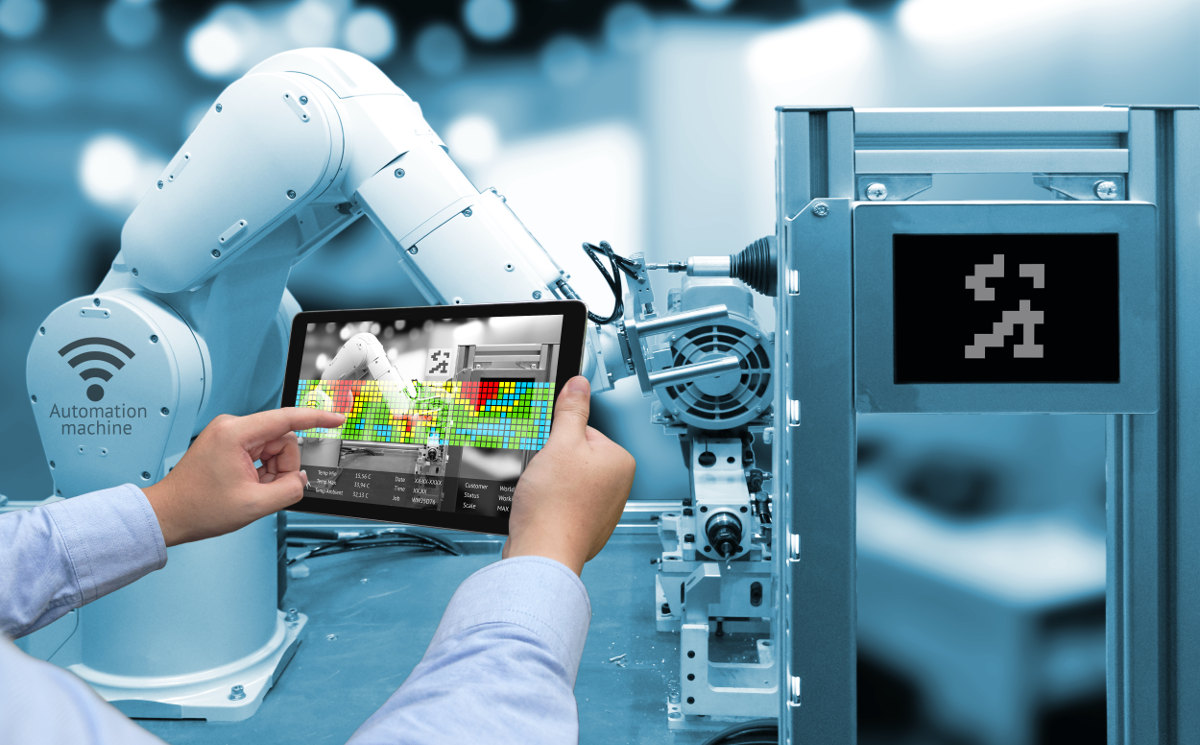

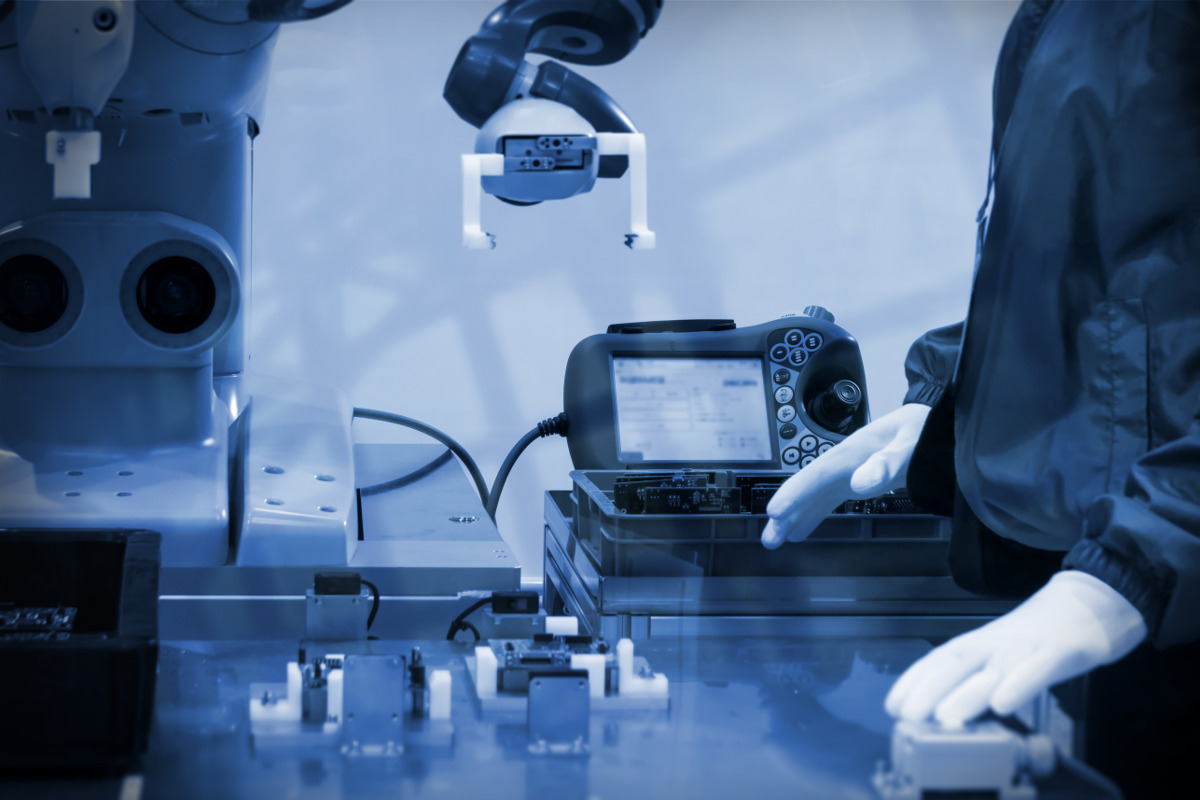

We provide hardware and software solutions from the world’s leading manufacturers because we know what it means for a manufacturing company to have a factory that is at a standstill or otherwise not utilizing its full potential. That’s why simplicity, reliability and low maintenance are paramount in our solutions.

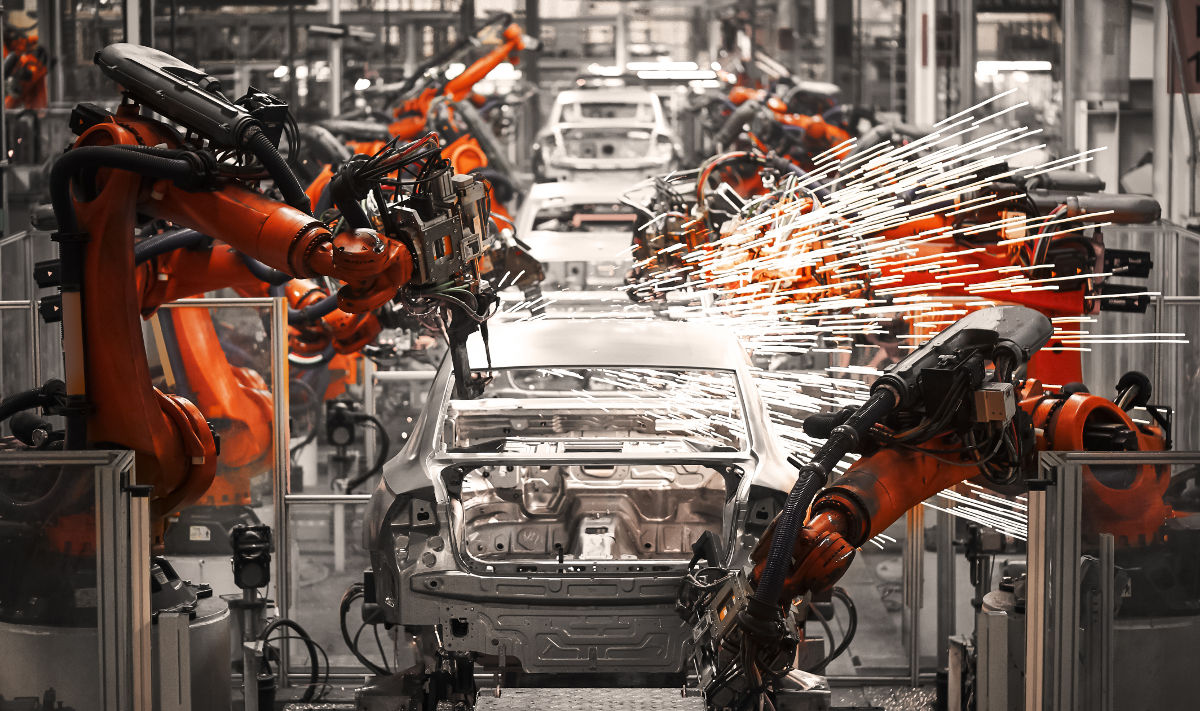

Industry 4.0, smart factories, robotics solutions and digitalization have already changed production processes all around the world. We want Estonian factories to take part in this leap.

Want to upgrade your factory to a new level of quality?

Woboton opens up manufacturing opportunities for you in a new, digitalized industry!